TPO METAL OVERLAY

Thermoplastic polyolefin (TPO) is the fastest-growing segment in the commercial roofing industry. At Crest Roofing we use the highest quality, longest lasting and best performing TPO roofing system on the market.

Suitable for a variety of low slope commercial roofing applications, UltraPly TPO membrane also offers design options with panels available in reflective white, tan or grey, which can help reduce a buildings cooling requirements.

TPO membranes take the best features from its direct competitors EPDM and PVC, while offering businesses an innovative and energy-efficient roofing solution. TPO roofs are durable; resisting dirt, bacteria, algae and debris build-up. The flexibility of the membrane makes it highly resistant to tears, punctures and impact damage. This flexibility also allows for a building’s movement and setting, without compromising the roof’s performance. Moreover, a TPO roof can withstand damaging ultraviolet, ozone and chemical exposure. Hot-air welded seams are very strong, with seam strengths being as much as 3-4 times greater than EPDM adhesive and tape seams.

A TPO membrane is considered to be a cool roof and is Energy Star rated. This means that the membrane reflects the sun’s ultraviolet rays. This can significantly lower HVAC costs and make the interior temperature more comfortable during hot summer months.

The most common TPO applications are either a TPO overlay on a metal roof or TPO on a flat roof.

There are several benefits to a TPO overlay. Membrane that is heat welded together to allow for a continuous roof system to protect from leaks - blankets the roof insulating the metal from the top down. It converts a metal roof that you can't touch in the middle of the summer to one that is cool and energy efficient. There is no tear off of the current roof system incurring no business interuption.

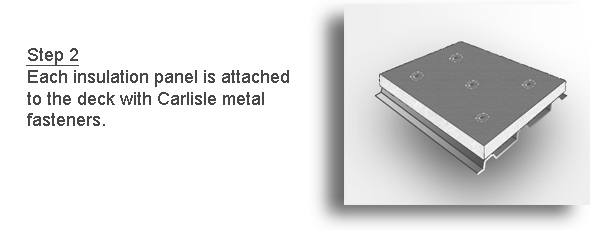

Here is a short explanation of how the TPO system is installed.